Workbench EXPERT MODELLERS SHOW YOU HOW

HOW TO GET THE BEST FROM A MODERN CONVERSION KIT

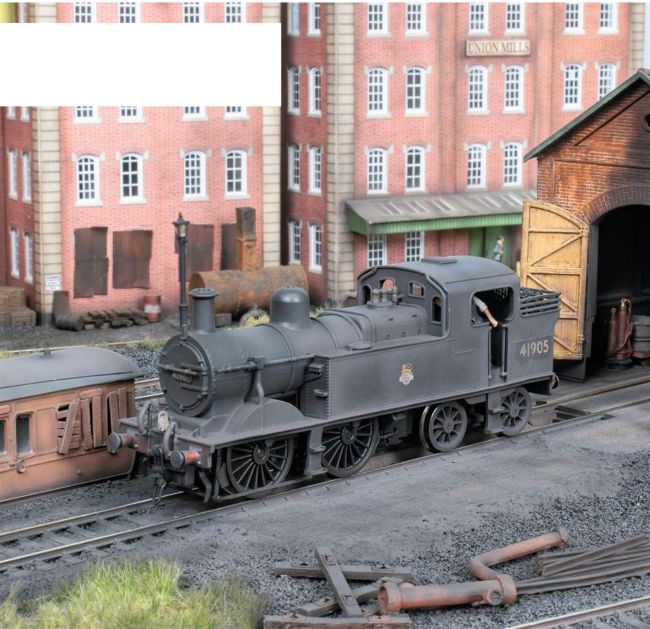

George Dent employs a 3D-printed bodyshell and a Hornby chassis to create a lesser known Stanier 0-4-4T.

PHOTOGRAPHY: GEORGE DENT

Modern technology has certainly helped to make complex locomotive and rolling stock conversion projects more accessible. Assembling etched metal kits or building from scratch are now options rather than necessity.

The rise in 3D printed components over the years has been a mixed blessing. OK, there’s far less labour involved in the assembly stages, but my own experience has proven that plenty of work may still be required in compensating for the inevitable ‘layered’ texture of the material.

Moreover, the brittle nature of the resins employed in 3D printers can make it difficult to customise components, but recent developments in material technology have improved matters to a degree and this bodyshell ‘kit’ from CDC Design is a good example of where we’re currently at in terms of detail and workability.

RESINS TO BE CHEERFUL

CDC Design offers a range of simple steam locomotive conversion projects under the Thanet Loco Works banner. The bodyshells are rendered in UV-cured resin and come complete with all details, such as whistles, safety valves, handrails, smokebox door handles, buffers and steam or vacuum pipes. The level of detail is impressive, while the material is fairly rugged. There’s a discernible texture to the surface, evidence of the layered printing process, but from the usual viewing distance, it’s not too obvious when the model is pootling around a layout.