3D PRINTING

MODELS ON DEMAND

From making tools and parts to creating replicas of museum violins, 3D printing offers luthiers both practical and educational possibilities. Harry White speaks to violin makers about how they are embracing the technology

'An advantageous alternative to plaster casts’: Joshua Beyer

What is 3D printing? Technically speaking, it’s the process of fabrication (also known as ‘additive manufacturing’) in which a computerised, digital design is made by machine that adds successive layers on to a flat surface to create a three-dimensional object. Thus far, the conversation around 3D printing within a musical milieu has been dominated by how far it can be used to create concert-worthy instruments. But this has taken focus away from an arguably more intriguing dimension. As Harry Mairson, a professor of computer science at Brandeis University in Massachusetts, wrote in this magazine (Making Matters, July 2021): ‘Violin making depends on having good tools’.

The 3D printing of instruments and the dataset that enables it are increasingly being seen as important factors in enhancing the contemporary luthier’s knowledge and workflow. ‘I’m not a professional violin maker; I’m a college professor who’s kind of fanatical about making musical instruments,’ says Mairson. ‘But I’m going to Cremona this year with the support of the Museo del Violino and the Istituto di Istruzione

ALL PHOTOS JOSHUA BEYER

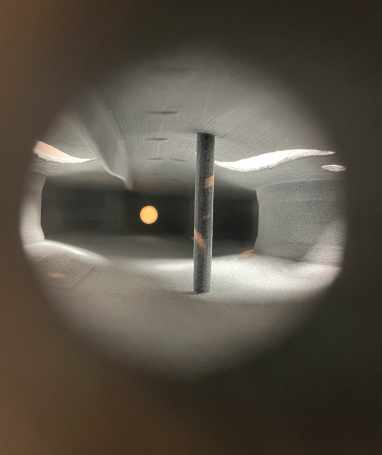

A freshly carved scroll next to its 3D-printed counterpart

Superiore Antonio Stradivari Cremona to talk to violin makers, students and teachers of lutherie about how to use radiology to look at CT scans of famous instruments. With CT scans, they can see the archings and the outlines. If you’re working on a cello and you want to know what the overstand should be, you can literally see what it’s like on Stradivari’s “Stauffer, ex-Cristiani” or his “Countess of Stanlein”. It’s just like having those instruments in your shop, right there to learn from. I’m convinced that applying data from CT scans and learning to use 3D printing technology will be useful to violin makers.

For example, with the data that drives a 3D printer I can rapidly fabricate prototypes of archings that I have designed geometrically for assessment. I can look at a prototype, look at its reflection, feel it, take measurements. And there’s a huge difference between that and studying scan data of a modern, imperfect instrument or something really old, and then digitally sanding or smoothing it to enhance its symmetry.’

Leggete l'articolo completo e molti altri in questo numero di

The Strad

Opzioni di acquisto di seguito

Se il problema è vostro,

Accesso

per leggere subito l'articolo completo.

Singolo numero digitale

June 2022 and Accessories supplement

Questo numero e altri numeri arretrati non sono inclusi in un nuovo

abbonamento. Gli abbonamenti comprendono l'ultimo numero regolare e i nuovi numeri pubblicati durante l'abbonamento.

The Strad

Abbonamento digitale annuale

€64,99

fatturati annualmente