HOW TO BUILD A LASER-CUT WOOD KIT

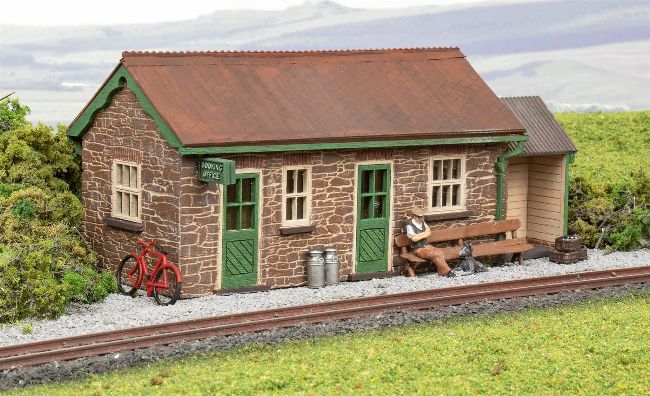

George Dent creates a tranquil Lynton & Barnstaple station scene, using a new laser-cut wood kit from Osborn’s Models.

PHOTOGRAPHY: GEORGE DENT

Laser-cut kits have become almost ubiquitous these days, when once they were ‘the new thing’ that seemed to represent a high-tech, futuristic element of 21st-century model making. Unsurprisingly, the quality of laser-cut kits and components has improved over the past couple of decades, with kits now featuring ever-greater levels of detail and complexity.

Micro plywood and fibreboard are the usual materials employed in laser-cut wood kits, perhaps with elements of plastic included, such as clear glazing, chimneypots and other small fittings. The wood-based materials possess a welcome surface texture, which has many benefits. Naturally, wood provides the most realistic representation of timber, but it also helps give stone and brick structures a less uniform surface. Combined with engraved mor-tar courses, roof tiles, timber planking, door and window frames, laser-cut building kits can look fabulous once assembled and painted.

The kit featured here is a 4mm:1ft scale rendition of Chelfham station on the former Lynton & Barnstaple narrow gauge railway, forming part of a useful range of ‘OO9’ gauge structure kits from Osborn’s Models. The range also includes various buildings based on those found at Woody Bay, such as a concrete platform shed, a pair of concrete lamp huts and a timber ground frame hut.